Our Expertise

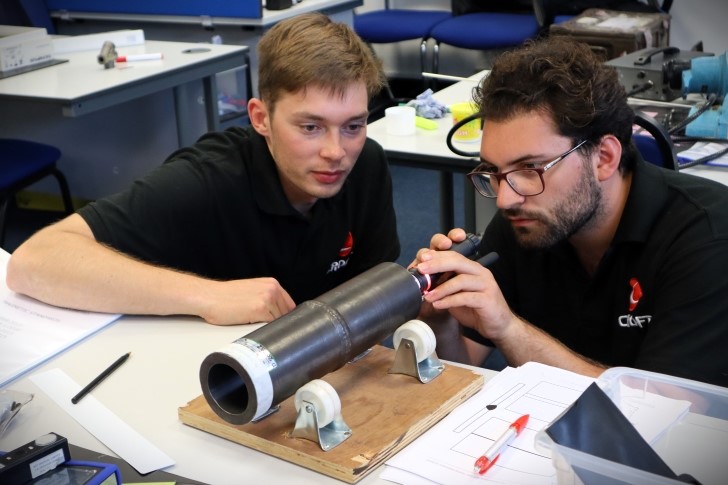

Without doubt, our biggest assets are our people.

We’re proud to work with so many professional Engineers and Scientists. Thanks to their vast experience and expertise they can deliver innovative packaging solutions time after time. Our technical team regularly provide input to various committees that set UK industry standards, and offer insight when regulations are under review.

Our team consists of a cross section of personnel who have spent many years within the nuclear industry working directly on nuclear plant and process and have gained a first-hand knowledge of what delivering safe and efficient solutions. We also seek to recruit and develop young engineers which allows a unique blend of knowledge and experience to be exchanged between the older and younger generations. Younger people are encouraged to stay and provide a resource for the future. In recognition of the need for continued improvement, we constantly strive to improve and enhance our training for all our staff.

In recognition of this, we have been awarded IKE Nuclear Assured® accreditation, the industry specific standard for assuring training in the nuclear sector. The Independent Advisory Panel recommending the award commended the company for its engagement and drive in ensuring consistency in learning and training development particularly given its size and capacity to deliver. We were the first SME in the nuclear field to be granted the award. The IKE Assured Nuclear accreditation is recognised by the National Skills Academy Nuclear (NSAN).

Our training helps us ensure consistency and benchmark against industry standards for training for all staff. The IKE scheme has been specifically developed to assure the quality of training that is delivered ‘in house’ by nuclear organisations and helps us to enhance our approach to training. It recognises the need for continuous improvement and for training to impact directly on business objectives and highlights performance in six areas: strategy and planning, engagement, design and delivery, innovation, standards and impact.

Management

Bob Vaughan

Founding Director

As Founding Director of Croft, Bob established the company in 1980. From the beginning, Bob has been responsible for the successful management, development and expansion of the company, including the formation of Croft Inc in 1993, based in the US, to provide services to the US Department of Energy (DOE).

With a PhD in Physics Bob has worked in the nuclear industry for over 40 years. Bob is a member of several Committees including the Transport Container Standardisation Committee (TCSC), American National Standards Institute (ANSI) and the International Organisation for Standardisation (ISO), writing the standard on Leakage Testing of packages for the shipment radioactive materials. Bob is also a member of the Institute of Nuclear Engineers and a consultant to the IAEA.

Bob has published a number of papers on transport packaging for radioactive materials and wastes.

Mark Johnson

Managing & Technical Director

As Managing and Technical Director Mark is ultimately responsible for all aspects of the business including both its day-to-day activities and its strategic direction and stakeholder interactions. In the capacity of Technical Director, Mark has responsibility for the technical performance and leadership of the work undertaken at Croft.

Mark is a Chartered Mechanical Engineer with over 40 years of science and engineering experience, covering mechanical, nuclear decommissioning, repository design development and radioactive waste management. He has worked in the areas of research and design consultancy, both in the private and public sector.

A recognised expert in his field, Mark has published a range of papers, been a prominent spokesperson at industry conferences and led UK and international project teams.

Alex Ferguson

Licensing Director

As Licensing Director Alex is primarily responsible for licensing packages for the transportation of radioactive materials. Alex has worked in the nuclear industry for over 36 years, starting out with UKEA and AEA Technology before joining Croft. His background includes providing engineering support to active handling facilities, designing remote handling facilities and pressurised equipment for UKEA/AEA Technology and subsequently providing technical support for the licensing activities at Croft.

The work in which Alex is typically engaged includes project management of licensing work for internal and external customers, addressing elements such as package impact, thermal, shielding and containment assessments, regulatory interpretation and liaison with regulatory approval authorities such as ONR.

Trevor Tait

Operations Director

Trevor joined Croft in 2010, most recently as Operations Director. He is responsible for all aspects of business delivery, incorporating the operational delivery of frameworks, major projects, business development and business improvement.

Trevor also directly manages Croft’s most strategically important projects, particularly with major clients within the defence sector. Most recently managing development of new Type B containers for defence applications.

As well as being a qualified APMP practitioner, Trevor is also a Chartered Mechanical Engineer. He has a background in commercial, project and engineering management within major nuclear industry Tier 2 organisations. As such he complements his management capability with over 30 years’ experience of many aspects of engineering within safety critical and highly regulated environments.

Guy Longman

Licensing Manager

As the Licensing Manager at Croft, Guy has lead responsibility for the commercial and technical delivery of package licence submissions and their approval through regulatory bodies. Additionally he is responsible for the management and development of our team of licensing engineers.

Guy is a degree qualified Chartered Mechanical Engineer with over 24 years’ experience within the Nuclear Industry, including 15 years’ experience in the design and licensing of radioactive transport packages; specifying and addressing elements such as package impact, thermal, shielding and containment assessments, together with regulatory interpretation and liaison with Competent Authority approval bodies. Additionally Guy has experience of the concept design and feasibility studies of new/existing plant and the commissioning and operation of new ILW waste processing plants.

Katherine Robson

Finance Manager

As Finance Manager, Kat is responsible for managing the finance function within Croft as well as supporting the HR department. After leaving school at 18, Kat took on an apprenticeship at an accountancy firm, completing both her AAT and Chartered ACA exams. Following on from her 10 years in practice, she decided to make the move into Industry. She enjoys implementing and improving systems as well as acting as a link between the Board of Directors and the team at Croft.

Kat is passionate about supporting local charities and is part of the team at Croft with regards to how we, as a Company, can engage with the local community.

Ian Dingwall

Manufacturing Manager & Business Line Lead SAFKEG® HS/LS

As Manufacturing Manager, Ian is responsible for managing the manufacture and maintenance of packagings to carry radioactive materials and has gained many years of continuous and varied project management and engineering experience in the Nuclear, Aerospace, Defence, and Marine Industries.

Ian started as an apprentice and undergraduate trainee at British Aerospace in Manchester and has since worked for four medium sized companies which has given him a wide range of experience and skills, predominantly in managing manufacturing projects.

Ian joined Croft in 2006 and has since managed many large projects involving the manufacture and qualification of Type B packages in both the UK and US.

Adam McConaghy

Technical Specialist & Business Line Lead Testing/CALT®

As a Technical Specialist Adam is responsible for specifying and managing testing of packaging designs and ancillary equipment for the transport of radioactive materials compliant with national and international regulations.

As well as a Chartered Mechanical Engineer, Adam is also an ASNT Level III in leak testing. Adam joined Croft in 2010 during which time he has used his expertise in leak testing to develop training and procedures for both periodic and pre-shipment leak tests.

Chris Shaw

Principal Engineer & Business Line Lead SAFTAINER®/SAFSHIELD®

As Principal Engineer Chris is responsible for the specifying and managing delivery of the design development programmes for packaging designs and ancillary equipment for the transport of radioactive materials compliant with national and international regulations.

Chris is also responsible for the managing development and testing programmes to validate packaging designs and has been instrumental in the design development and associated material substantiation research and development of ductile cast iron packaging at Croft.

Chris joined Croft in 2011, prior to this working at Dounreay Site as Tier 1 successfully delivering diverse and complex design projects to support the decommissioning activities on site. A degree in Mechanical & Manufacturing Engineering coupled with experience working with injection moulding for the AV market has enabled Chris to pull from many areas of expertise to deliver projects safely and successfully.