Services

Our services, at a glance

We have developed a broad range of skills and expertise in radioactive materials transport packaging and utilise these in the development of our own products and those of our customers. Our core technical expertise and capabilities are listed below.

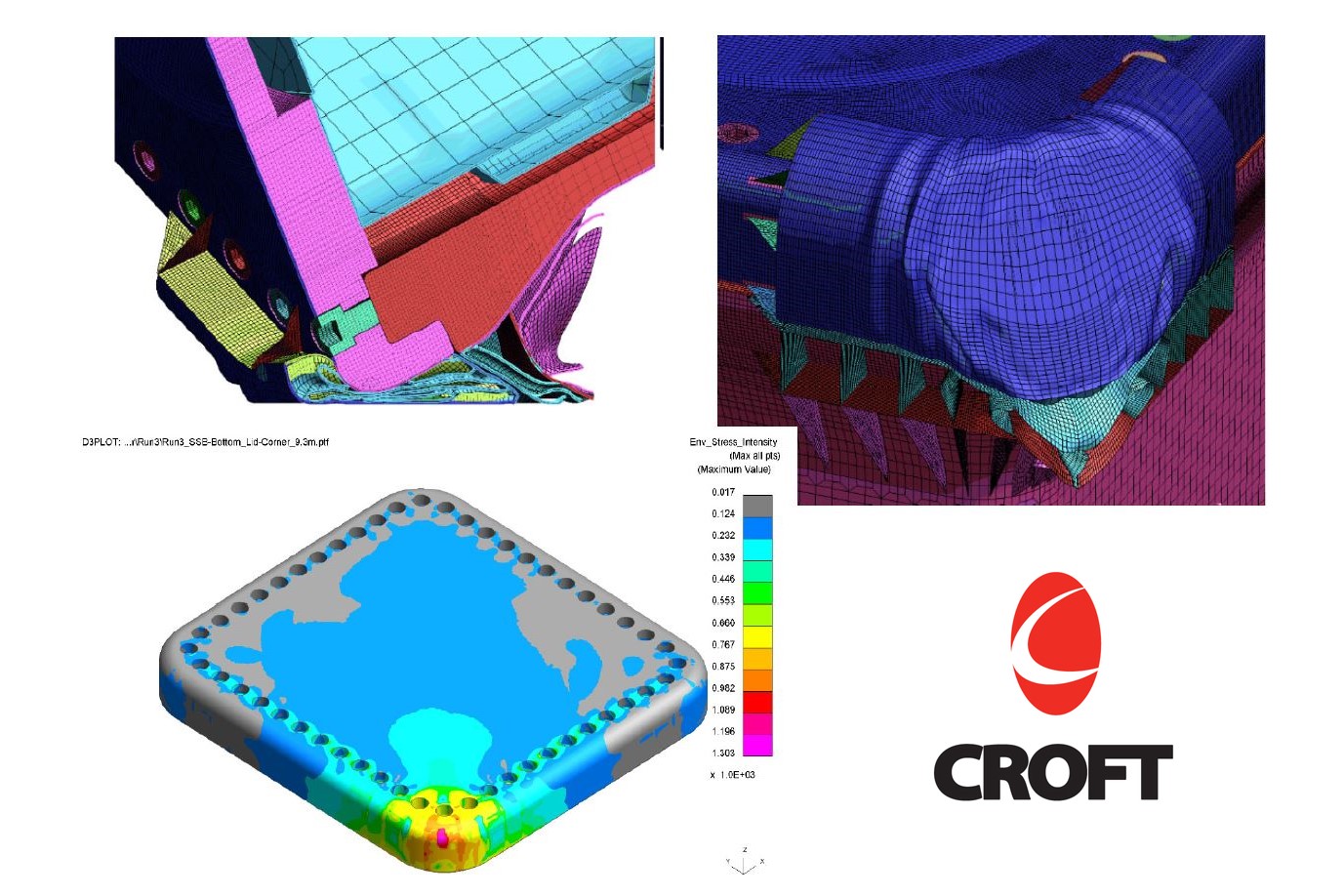

Design & Development

Design development of packaging designs from initial conceptual schemes through to fully detailed designs to meet customer and regulatory requirements. The designs are underpinned by extensive research and development.

Our packages are designed to meet the requirements of the IAEA regulations for the safe transport of radioactive material. Consideration is given to the principal safety functions, performance, and interface requirements, including:

- Safety Requirements

- Radiation Shielding

- Containment Performance

- Structural and Impact Performance

- Thermal Performance and Heat Transfer

- Internal Heating

- External Heat Sources

- Safe Fissile Mass and Criticality

- Vibration Analysis

- Quality Assurance

- Operational interfaces

- Human Factors

- Ageing Mechanisms and Through Life Performance Degradation

Testing

Our testing services include structural, impact, thermal, pressure, and leakage testing. Testing can be performed at the component level or full scale package testing. We also utilise testing extensively for benchmarking of FEA models.

We offer a complete packaging testing service including:

- Regulatory performance testing as defined in the IAEA regulations

- Liaison with the Competent Authority to define test requirements and programmes

- Assessment of the ability of packages to retain their radioactive contents and deliver the intended safety performance through:

- Testing of prototype designs

- Testing of scale models and component and assembly level testing

- Fully instrumented test specimens, including high frame rate photography and post-test metrology inspection.

- Calculation and analysis

- Comparison with previous test data and FEA model benchmarking

- Containment verification to ANSI N14.5 and ISO 12807 using pressure drop/rise and high integrity MSLD techniques using our ASNT Level III and NDT Level II certified staff.

Licensing

We provide a comprehensive range of licensing services for transport packagings, including the self-approved licensed designs and Competent Authority approvals through regulatory bodies worldwide.

Croft are allowed to self-approve under the transport regulations (such approvals verified and audited by our Competent Authority). Additionally, Croft have successfully achieved Type B approvals from the UK Competent Authority, the NRC and various other overseas Competent Authorities.

Our Quality Management System (QMS) has been audited by ONR for the licensing and certification of Type IP and Type A packages for the transport of radioactive materials, demonstrating, through inspection and audit, that our designs and processes employed to develop and approve these comply with the requirements of the applicable UK legislation. Specifically, for the design, operation, and maintenance of radioactive materials under the various dangerous goods directives, including ADR and RID. Additionally our QMS is compliant with the requirements of 10 CFR 71 Subpart H and is periodically audited by US NRC.

We offer a complete packaging licensing service, including:

- Obtaining Competent Authority approval for package designs and shipment

- Assessment of safety documentation and the issue of certificates where appropriate

- Obtaining validations of Competent Authority Approvals in other countries

- Preparation of technical documents

- Management of approval applications

Manufacture & Procurement

The manufacture of Croft packages and procurement of commercial off-the shelf components are carried out to Croft’s certified and approved quality management system.

We offer a complete manufacturing and procurement service including:

- Manufacturing of a complete range of packagings from small IP and single use Type A designs to large SAFSHIELD® heavily shielded Type B(U) flasks and IP-2 ISO SAFTAINER® packaging.

- Manufacturing of standard package designs that meet the IAEA Regulations

- Rigorous Quality Assurance Systems are applied to all stages of manufacture and procurement, applying a graded approach.

- Manufacture of specialised packagings to meet all relevant regulations and standards.

Maintenance

Maintenance service for all packaging types (IP, Type A and Type B). We also develop comprehensive maintenance manuals which address the latest regulatory requirements regarding package ageing effects and consideration of the effects of human factors upon safety and performance.

We offer a full aftersales service including:

- Annual inspection and maintenance of IP, Type A and Type B packages covering:

- Periodic leakage testing and verification of containment vessels

- Leakage testing of elastomeric seals

- Replacement/refurbishment of defective parts

- Inspection and maintenance of Croft IP-2 reusable ISO SAFTAINER®

- Calibration and servicing of the CALT leak testing equipment

- Repair/refurbishment of damaged Croft packaging designs

Package Rental

From a stock of commonly used packagings, including our SAFPAK®, SAFKEG®, SAFSHIELD®, and SAFTAINER® packaging designs.

We hold some stock of our more commonly used transport packaging designs which can be available for immediate hire (depending on stock levels).

Please contact us for more information.

Training

We offer a range of supporting training services under our IKE Nuclear Assured® accreditation. The training can be utilised by customers for employee learning and development and SQEP compliance.

Principally training services are offered in the following:

- CALT leakage testing certified training of operators using our ASNT Level III certified staff.

- Mass Spectrometer Leak Detection (MSLD) using our ASNT Level III and NDT Level II certified staff.

- Training in Croft packaging designs, covering both operations and maintenance requirements using our SQEP engineers.

Bespoke training programmes can be developed to suit customers’ needs. Please contact us for further information.

Consultancy

We offer an extensive range of consultancy and advisory services in support of packaging and transport of radioactive materials across a broad scope of technical and scientific disciplines.

- Shielding calculations

- Mechanical and thermal stress analysis for packages when subject to normal and accident conditions of transport, and for extend tests

- Support to licensed site operations (e.g. safety case preparation/review covering probabilistic risk assessment, safety management, and in particular movement of radioactive materials within the licensed site)

- Peer review

- Engineering substantiation